The ideal solution for molding and casting processes

Today, as it was thirty years ago, our casting machines represent the best solution for casting titanium, platinum, gold and silver.

Back

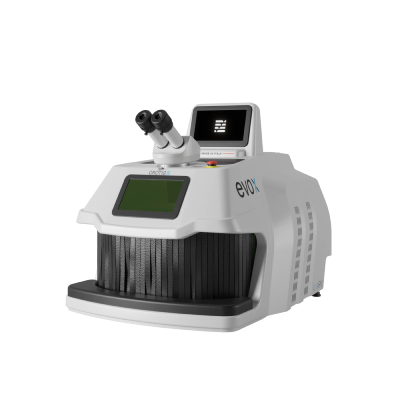

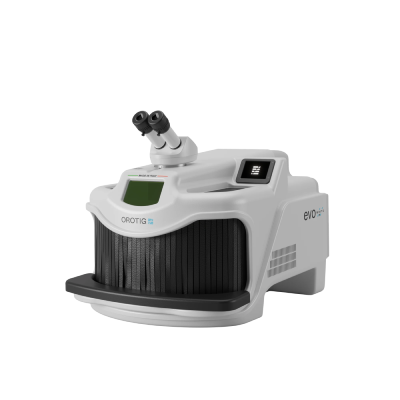

An enhanced evolution of the renowned Evo X laser welder, the new model features SoftSpot technology for smooth, clean welds on all reflective metals and an optimized duty cycle.

The Midi Tech welding machine, reliable and easy to use, is the perfect entry-level solution for small-scale work and repairs in the jewelry and dental fields.

The compact, powerful laser welding machine ensuring maximum precision and reliability, effortlessly delivering superior quality even on reflective metals.

Thanks to its compact design and high-quality components, Evo White is the ideal welder for repairs and customizations in the jewelry and dental fields, ensuring maximum precision and reduced processing times.

The high frequency, peak power and advanced cooling system make Revo X our welding machine with the highest performance, capable of continuous operation for +15 hours.

The Flash series offers a range of fibre-optic laser sources that can be integrated into production processes requiring a high degree of speed and automation. Compatible with all chain manufacturing machines, they guarantee uniformity and high-quality welds

The Aries industrial welding machine is able to operate continuously while meeting high quality standards, even on large workpieces, due to the open welding chamber and 3-axis table movement.

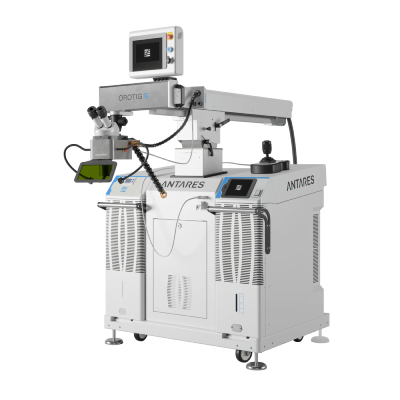

Antares is an industrial laser welding machine designed for repairing moulds or large workpieces. With a motorized arm, it can weld at points that would otherwise be difficult to reach.

New generation of compact laser engraving machines with an essential design, combining high performance, precision, and ease of use thanks to the proprietary MARKo software.

As the evolution of the RR engraving machine, it ensures precise engraving and cuts up to 2 mm on metals and alloys. Equipped with a coaxial camera for accurate visualization, it is available with various power sources, including MOPA lasers, ideal for high-precision engraving.

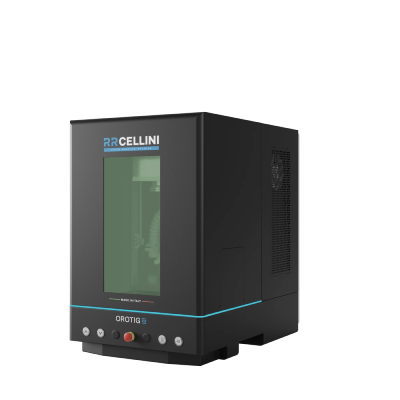

The RR Cellini laser engraver machine is a high-precision laser system for quality three-dimensional engraving on metal objects.

With a very short laser pulse in the picosecond range, which does not heat up the metal, RR Pico guarantees precise, burr-free, burn-free marking, enabling work even near resins or other heat-sensitive materials.

Our innovative integrated laser cutting and marking system for large-scale production is capable of precise, high-speed cutting up to 4 mm deep.

The new standard in precious metal casting: Prometheus, a fully automatic tabletop casting machine for quick and easy custom jewelry creation.

Ackeron-PT Cast is the ideal solution for platinum casting, designed to ensure maximum quality and precision. With its patented horizontal casting system and a 500 g capacity chamber, it guarantees a finished product quality that meets the high standards of fine jewelry.

Casting machine for gold and silver, also compatible with brass and bronze, designed for the needs of high jewelry, fashion, and eyewear industries. The patented horizontal casting system ensures consistent quality and repeatable casting cycles.

With a chamber capable of casting up to 130 grams of titanium at a single time in an argon gas atmosphere, TI Cast is the ideal choice for obtaining extremely high-quality castings.

The two-chamber burnout furnace with an innovative system that allows the burnout of different types of material at the same time, thanks to the ability to set different temperatures for the two chambers or to turn on only one chamber at a time.

Follow the instructions:

04-06 March 2026

Orotig will be present at MECSPE 2026

Today, as it was thirty years ago, our casting machines represent the best solution for casting titanium, platinum, gold and silver.

Today, as it was thirty years ago, our casting machines represent the best solution for casting titanium, platinum, gold and silver.

Our range of casting machines includes furnaces specifically designed for titanium processing, our traditional product initially developed for the dental sector and now widely requested in the jewelry sector. We also offer induction furnaces of various sizes that ensure flawless melting of precious metals such as gold, silver, and platinum.

Thanks to innovative, patented technology, which enables rapid and smooth cylinder filling, Orotig casting machines deliver a finished product with an excellent finish and smooth surface, requiring minimal additional processing, leading to both time and cost savings.

The Orotig casting machine range meets the needs of both large-scale production and small jewelry workshops that need to create custom designs in a short time.

Our casting products are designed to ensure the highest quality in the processing of precious metals. Our furnace, equipped with a patented planetary system, ensures uniform rotation of the cylinders within the heating chambers. This system provides even temperature distribution across the molds, improving the quality of the cast and the final product. Our micro-casting machines are ideal for the jewelry and fashion sectors, which require fast and precise productions. Thanks to an innovative casting system featuring vertical rotation and perfect contact between mold and crucible, casting occurs without sealing gaskets.

Additionally, the integrated overpressure ensures complete filling of every cavity in the mold, minimizing the risk of porosity and defects in the finished product.

A platinum casting machine with a patented horizontal casting system and a chamber capable of melting up to 500 g of platinum in a single operation.

Two-chamber mold furnace for the simultaneous firing of various types of plaster, with independent temperature control for each chamber.

Compact and easy-to-use bench casting machine with an innovative casting system for gold, silver, and platinum.

Titanium casting machine capable of melting up to 130 g of metal in a controlled argon gas atmosphere.