Cutting and marking for quality serial production

Our innovative integrated laser cutting and marking system for large-scale production is capable of precise, high-speed cutting up to 4 mm deep.

Cutting and marking for quality serial production

Our innovative integrated laser cutting and marking system for large-scale production is capable of precise, high-speed cutting up to 4 mm deep.

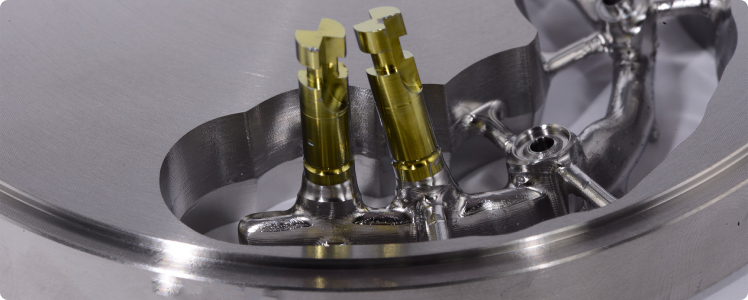

High definition cutting and marking

Its perfectly perpendicular cutting walls and simultaneous use of two laser sources allow it to perform both operations.

Maximum productivity

Dramatically reduces processing times because it can cut in a single pass and work continuously due to the integrated chiller and sheet metal winder.

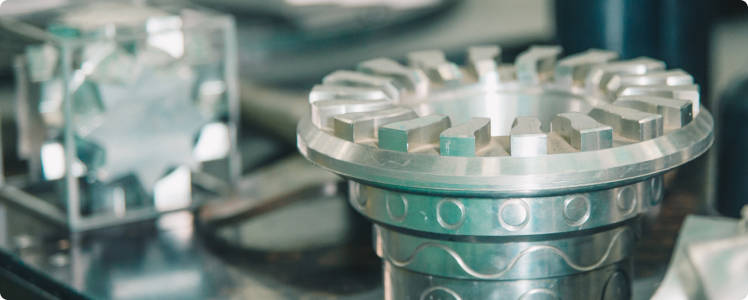

Material recovery

Special technology combining a laser beam with a gas jet and high-performance suction system allows it to recover much more material than with other cutting methods.

Cutting and marking in a single product

With the combination of two laser sources in a single product, operators can perform cutting and marking on the same metal, optimizing production times without sacrificing the quality of the end result.

Cutting and marking in a single product

With the combination of two laser sources in a single product, operators can perform cutting and marking on the same metal, optimizing production times without sacrificing the quality of the end result.

Production efficiency

With TDL, machining times are reduced significantly due to the ability to make precise cuts up to 4 mm deep in a single pass. Furthermore, the integrated chiller and sheet metal winder make it possible to work continuously, thus optimizing production times.

High productivity

With the integrated chiller, enabling 24/7 operation.

Minimal operator intervention

Automation systems allow certain machining operations to be memorized and the winder automates the serial cutting process.

Sheet metal optimization

The software makes it possible to optimize cutting areas and store sheet metal that has already been processed.

Material optimization

The special technology of TDL, specially designed by our research and development team to combine a laser beam with a gas jet and high-performance suction system, allows for far greater metal recovery than with other cutting methods.

Less material waste

Plate areas are optimized as a result of the plate driver with integrated software.

Waste recovery

The metal does not sublimate due to the laser beam and a gas jet that pushes down the metal particles.

Suction system with self-cleaning filter

Operator intervention is minimized due to a compressed air and dust recovery system.

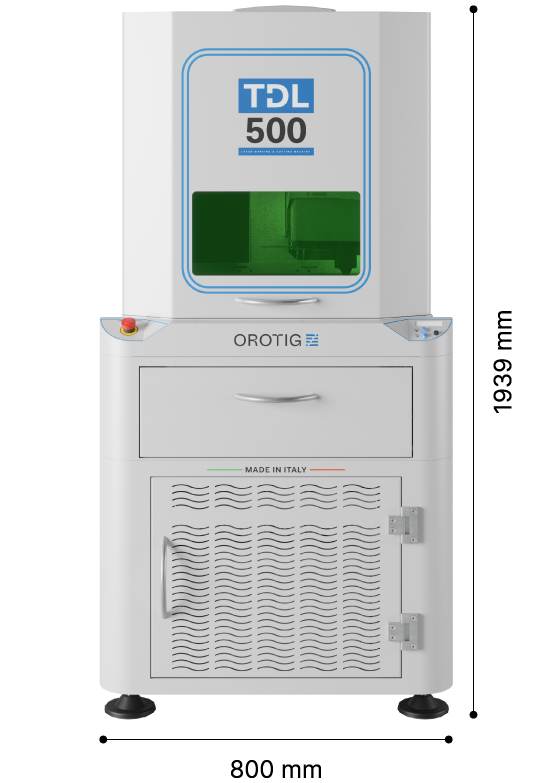

Size and Dimensions

- Features

- Technical Data

- Accessories

- Downloads

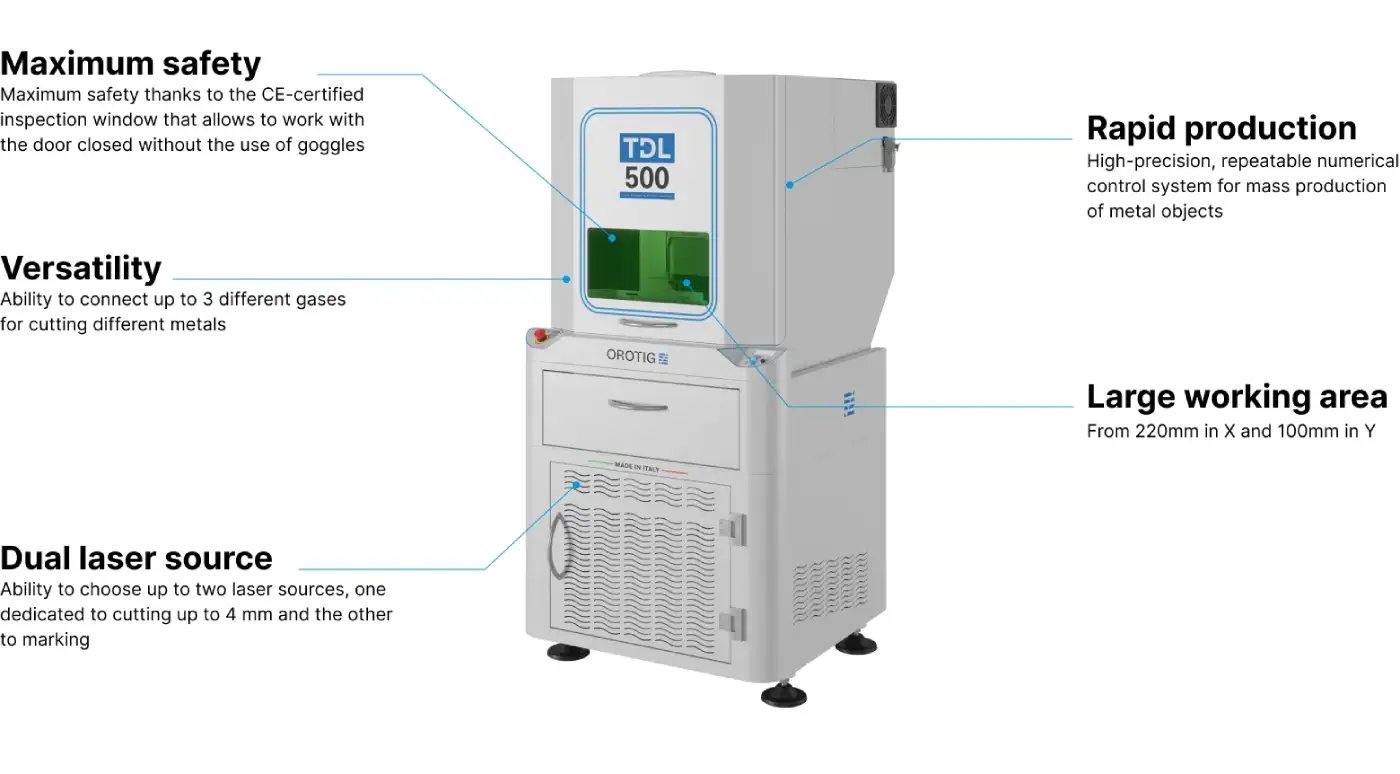

Maximum safety

Maximum safety thanks to the CE-certified inspection window that alllows to work with the door closed without the use of goggles

Rapid production

High-precision, repeatable numerical control system for mass production of metal objects

Versatility

Ability to connect up to 3 different gases for cutting different metals

Large working area

From 220mm in X and 100mm in y

Dual laser source

Ability to choose up to two laser sources, one dedicated to cutting up to 4 mm and the other to marking

TECHNICAL DATA

TDL

MAX ENGRAVING AREA

110 × 110 mm [x2]

CUTTING AREA

X=200 mm, Y=110 mm

CUTTING / MARKING SPOT SIZE

0.1 mm / 50 μm

AVERAGE CUTTING POWER

300 W, 450 W

MAX PEAK POWER (CUT)

3000 W, 4500 W

SHEET WIDTH

min 20 mm - max 125 mm

MAX X-Y-Z AXIS STROKE

225 - 120 - 144 mm

RAPID FEED RATE (X-Y-Z)

max 10000 mm/min

X-Y-Z AXIS ACCELERATION

max 2 m/s2

X-Y-Z CNC HANDLING

165 N/cm

POSITIONING ACCURACY AND REPEATABILITY

0.01 mm

PNEUMATIC SYSTEM OPERATING PRESSURE

7 bar

MINIMUM AIR COMPRESSOR CAPACITY

160 l/min

AVAILABLE CUTTING GAS INLETS (MAX. PRESSURE 16 BAR)

3

LASER CLASS

Class 1 (closed), Class 3R (open)

POWER SUPPLY

230 VAC ± 10%, 1+N ph, 50/60 HZ, 4.5 kW (6 kW with accessories)

DIMENSIONS (W x H x D)

800 × 1940 × 946 mm

WEIGHT

600 Kg

TDL

MAX ENGRAVING AREA

110 × 110 mm [x2]

CUTTING AREA

X=200 mm, Y=110 mm

CUTTING / MARKING SPOT SIZE

0.1 mm / 50 μm

AVERAGE CUTTING POWER

300 W, 450 W

MAX PEAK POWER (CUT)

3000 W, 4500 W

SHEET WIDTH

min 20 mm - max 125 mm

MAX X-Y-Z AXIS STROKE

225 - 120 - 144 mm

RAPID FEED RATE (X-Y-Z)

max 10000 mm/min

X-Y-Z AXIS ACCELERATION

max 2 m/s2

X-Y-Z CNC HANDLING

165 N/cm

POSITIONING ACCURACY AND REPEATABILITY

0.01 mm

PNEUMATIC SYSTEM OPERATING PRESSURE

7 bar

MINIMUM AIR COMPRESSOR CAPACITY

160 l/min

AVAILABLE CUTTING GAS INLETS (MAX. PRESSURE 16 BAR)

3

LASER CLASS

Class 1 (closed), Class 3R (open)

POWER SUPPLY

230 VAC ± 10%, 1+N ph, 50/60 HZ, 4.5 kW (6 kW with accessories)

DIMENSIONS (W x H x D)

800 × 1940 × 946 mm

WEIGHT

600 Kg

Plate decoiler

Air drier

Dust recovery system

Discover other similar products

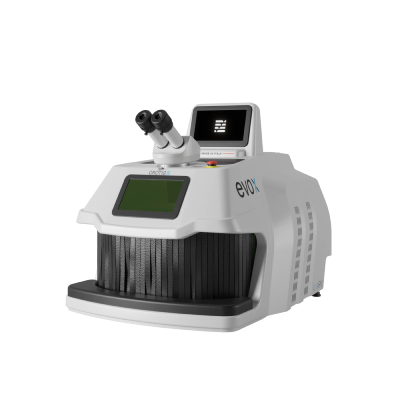

DISCOVER CELLINI

Laser Marking Machine

DISCOVER REVO X

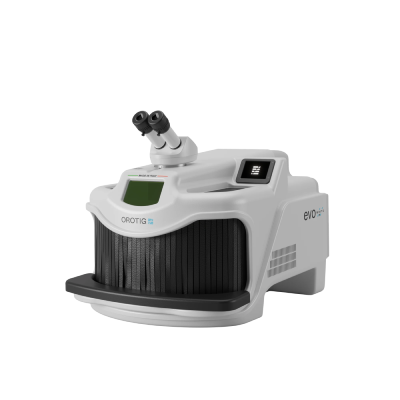

Laser Welding Machine

DISCOVER RR PICO

Laser Marking Machine

DISCOVER ARIES

Laser Welding Machine

DISCOVER ANTARES

Laser Welding Machine