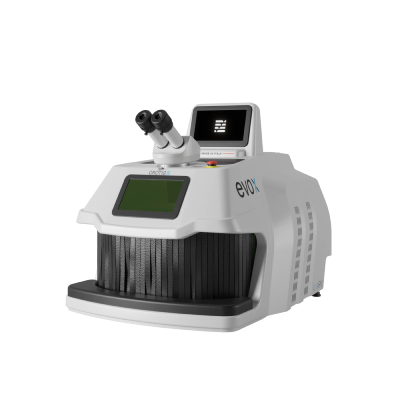

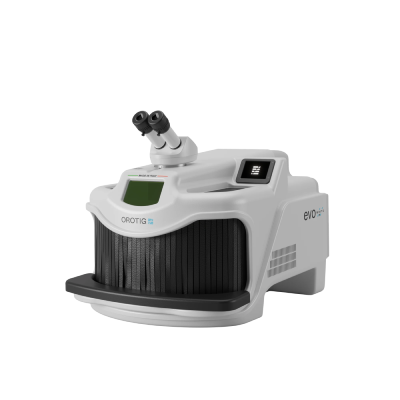

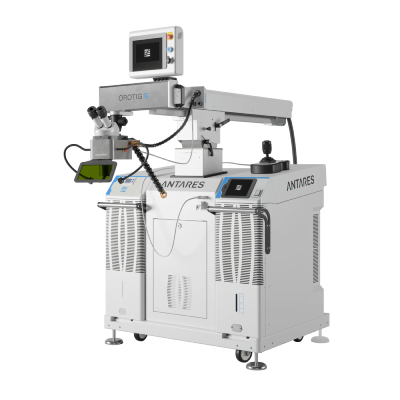

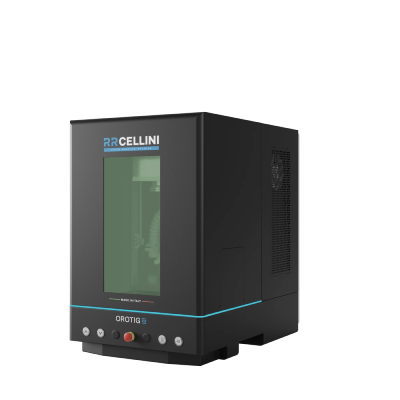

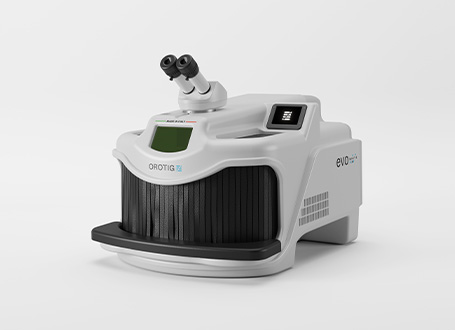

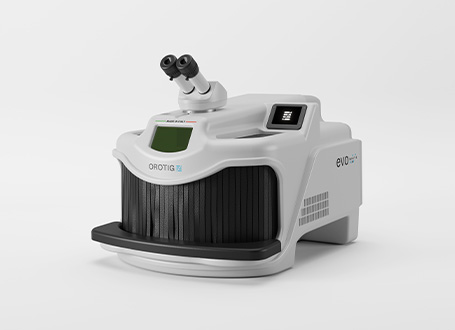

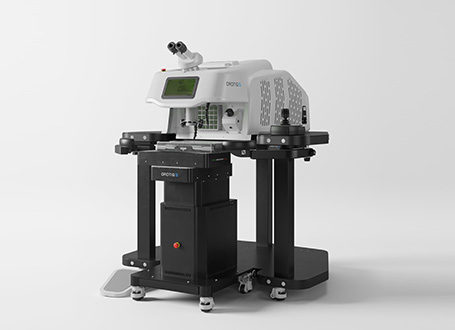

High quality laser welding machines for all work environments.

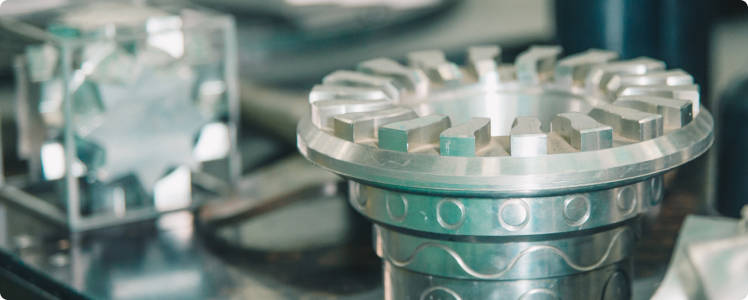

Our laser welding machines stand out for their outstanding quality and precision, as well as the durability and reliability of the components. They deliver excellent results on a wide range of metals, from precious materials like gold, silver, and platinum to titanium, stainless steel, aluminum alloys, nickel, and cast iron.